What is mass loading in wastewater treatment?

Wastewater treatment is a crucial process in modern society, responsible for removing harmful pollutants from our wastewater before it is returned to the environment. One important factor in this process is mass loading, which refers to the amount of pollutants present in the wastewater at any given time.

What is Mass Loading?

Mass loading is the measure of the total mass of pollutants that are present in a given volume of wastewater. It is typically expressed in units of mass per volume, such as milligrams per litre (mg/L) or pounds per cubic foot (lb/ft^3).

The mass loading of a particular pollutant in wastewater can vary greatly depending on the source of the wastewater and the type of pollutants present. For example, wastewater from an industrial facility may contain high concentrations of heavy metals, while domestic wastewater may contain high levels of organic matter such as fats, oils, and greases.

The mass loading of pollutants in wastewater is an important factor in the design and operation of wastewater treatment plants. In order to effectively remove pollutants from wastewater, the treatment process must be designed to handle the specific mass loading of pollutants that are present.

Why is Mass Loading Important?

The mass loading of pollutants in wastewater is important for several reasons:

- Design of treatment facilities: The mass loading of pollutants in wastewater is an important factor in the design of wastewater treatment facilities. Treatment facilities must be designed to handle the specific mass loading of pollutants that are present in the wastewater. If the mass loading is too high, the treatment process may be overwhelmed and unable to effectively remove pollutants.

- Efficiency of treatment: The mass loading of pollutants in wastewater can also affect the efficiency of the treatment process. If the mass loading is too high, the treatment process may not be able to remove all of the pollutants, resulting in a discharge of untreated or partially treated wastewater into the environment.

- Environmental impact: The mass loading of pollutants in wastewater can have a significant impact on the environment. If untreated or partially treated wastewater is discharged into the environment, it can have a negative impact on water quality, aquatic life, and public health.

How is Mass Loading Measured?

The mass loading of pollutants in wastewater can be measured using a variety of techniques. One common technique is to measure the concentration of the pollutant in the wastewater and then calculate the mass loading based on the volume of wastewater being treated.

For example, if the concentration of a pollutant in wastewater is 50 mg/L and the flow rate of the wastewater is 4000 litres per day (gld), then the mass loading of the pollutant would be:

Mass loading = concentration x flow rate

Mass loading = 50 mg/L x 4000 gld

Mass loading = 50,000 mg/day

Other techniques for measuring mass loading include using mass flow meters or load cells to measure the mass of the wastewater being treated, and then analysing the wastewater to determine the concentration of pollutants present.

How is Mass Loading Controlled?

The mass loading of pollutants in wastewater can be controlled through a variety of measures, including:

- Pollution prevention: The most effective way to control mass loading is to prevent pollutants from entering the wastewater in the first place. This can be done through pollution prevention measures

such as source control, implementing best management practices, and reducing the use of harmful chemicals. - Treatment process optimization: The treatment process can be optimized to handle higher mass loadings by adjusting the process parameters, such as increasing the retention time, adjusting the pH, or adding additional treatment stages.

- Advanced treatment technologies: Advanced treatment technologies, such as membrane filtration, activated carbon adsorption, and ozonation, can be used to remove pollutants at higher mass loadings than conventional treatment processes.

Conclusion

Mass loading is an important factor in the design and operation of wastewater treatment plants. It is the measure of the total mass of pollutants that are present in a given volume of wastewater and can vary greatly depending on the source of the wastewater and the type of pollutants present. The mass loading of pollutants in wastewater is important for the design of treatment facilities, the efficiency of treatment, and the environmental impact. Mass loading can be controlled through pollution prevention, treatment process optimization, and advanced treatment technologies. By controlling mass loading, we can ensure that our wastewater treatment processes are effective and sustainable.

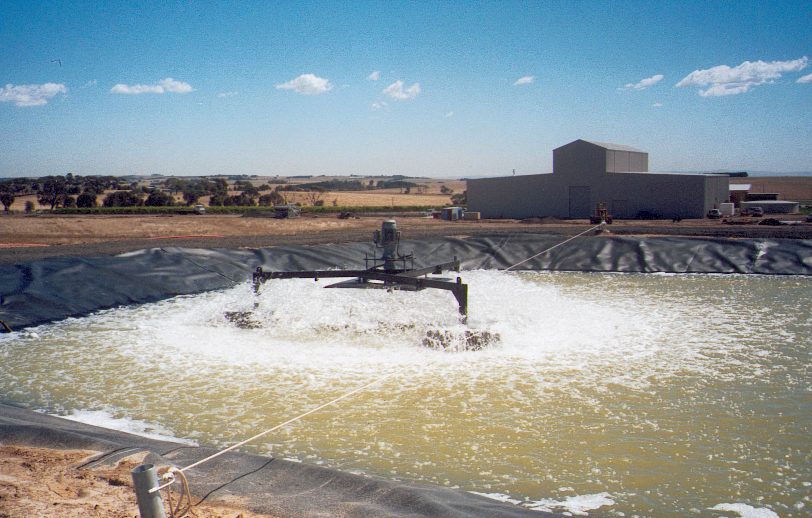

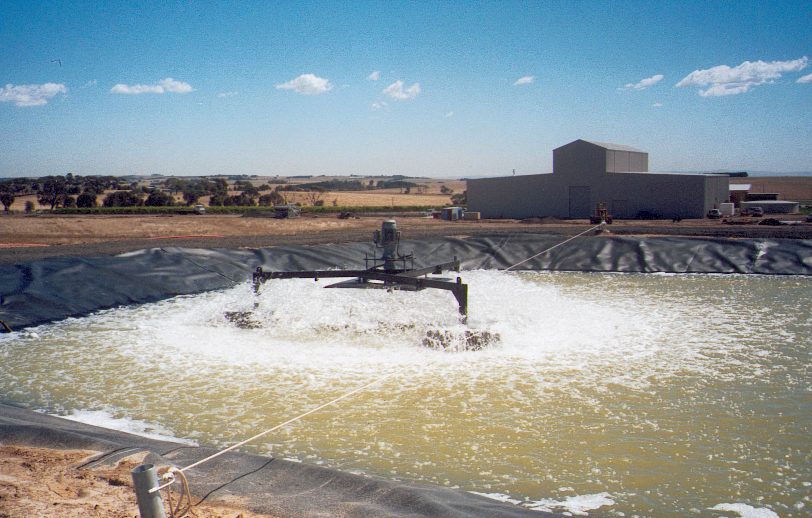

By-Jas Engineering provides various types of aerators for every purpose. We guarantee that our aerators are designed for longevity and reliability. We assure you the best quality equipment and services from By-Jas Engineering. We can help bring your project into reality. Just get in touch with us at (03) 5979 1096 or check out our services on our website: www.byjas.com.au.

Our services cover all of Australia, including the main capital cities, regional town centres and all other remote regional areas of the country.

SHARE:

What you can read next

Waste water treatment for Wineries

Wineries across Australia are producing record ...

Specialising in the Winery Industry

We cater to the winery industry in order to red...

Irrigation efficiency for Wineries

As we know wineries produce wastewater from the...

What is Involved in the Process of Winery Wastewater Treatment?

Winery wastewater is generated from the winery’s...

Want to remove waste water efficiently

Are you looking for a cheaper and more environmen...

Why Choosing a Wastewater Equipment Manufacturer Provides a Better Option?

Why Choosing a Wastewater Equipment Manufact...

Why Are Bacteria Used in Sewage Treatment?

Wastewater treatment is society’s way of giving...